Cementing Services

Proper cement and cementing practices are an integral part of ensuring successful well integrity. The API states that, “complete displacement of drilling fluid by cement and good bonding of the cement interfaces between the drilled hole and the casing immediately above the hydrocarbon formation and key parts of well integrity and seal integrity.” The cement is meant to completely isolate the wellbore from the surrounding geological formations with the absence of gaps and voids. In order to achieve this total isolation, the proper type of cement must be used. These types of cement are best suited for use in the varying temperatures and subsurface conditions throughout the wellbore.

Cementing Process

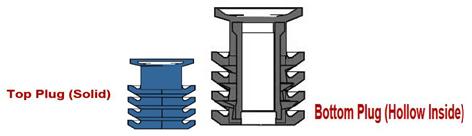

Wiper plugs are components used to separate the drilling fluid from the cement slurry. Polydrill use these wiper plugs to minimize the mixing of cement with the drilling fluid as well as ensure that no cement remains on the inside of the casing. Centralizers are also used by Polydrill to center the casing to ensure that it will be completely surrounded by cement allowing for complete isolation. The number of centralizers is specified by state regulations. Once the cement is poured, an eight hour wait time must be observed before further activities to ensure that the cement is fully solidified.

Cement Plugs and Types of Centralizers

Polydrill has carried out various successful primary cementing operations that have resulted in a cement sheath to bond and support casing and provide zonal isolation. Good zonal isolation helped prevent the loss of production, control inter-zonal flow and/or flow to the surface, reduced water production and improved confinement of stimulation treatments.

Some of the common Types of Cementing Processes/Techniques carried out by Polydrill crew depending on the need of the hour over the last 6 plus years :

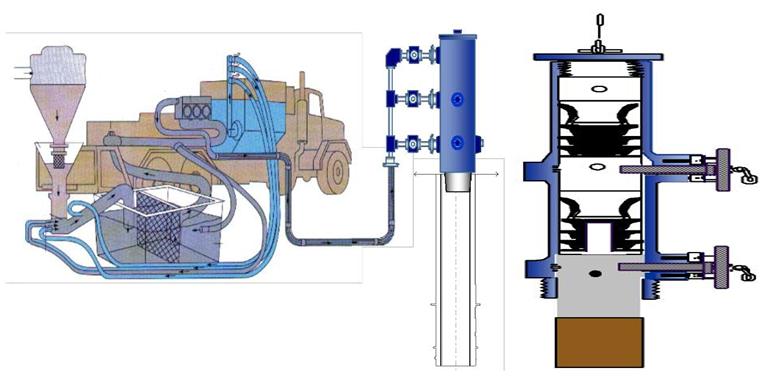

Polydrill Surface Cementing Equiments

Polydrill with the help of a mix of recent and modern technology uses the said 2 equipment models to carry out various Single & Multistage Cementing jobs. Polydrill also has a fleet of Bulk Handling equipments which gives them disregard upper hand to completely carry out Cementing jobs independently.

These equipments are tailor made for Polydrill use of Rental & Operation Service.

We also use Wiper Plugs which are used to separate cement from preceding or following fluids. The bottom plug removes mud from the wall of the casing, and prevents this mud from accumulating beneath the top plug.

Casing Centralizers used by us is only to:-

Primary Cementing Techniques followed by Polydrill

a. Conductor :-The conductor is usually the first and shortest casing string. Its purpose is to protect shallow sands from being contaminated by drilling fluids, and help prevent wash-outs which can easily occur near the surface because of loose, unconsolidated formations. The depth is normally less than 300 ft. It can be used for the attachment of a blowout preventer.

b. Surface Casing :-

Surface casing is usually the second string of pipe set in the well. Shallow surface casing is cemented in the same manner as conductor casing. For deeper strings of surface casing, a lightweight lead cement is used, followed by heavier-weight completion cement to strengthen the bottom of the surface casing around the shoe. This creates a strong seal with the pipe and formation for solid support of the casing.

c. Intermediate Casing :-

The intermediate casing is the first string of pipe set after the surface casing. Intermediate casing strings extend from the surface to a formation able to hold the mud weights expected at greater depth. Unlike the conductor and surface casings, additives such as friction reducers, fluid-loss additives, and retarders are required for intermediate slurries. Where the annulus is small, friction reducers lower pump pressures and reduce the chance of losing fluids in a lost-circulation zone.

d. Production Casing :-

The production casing is the last full string of pipe set in the well, and extends to the surface. The production casing is normally run and cemented through a zone to be produced, and then perforated to allow communication with the formation. Sometimes it is set just above the zone, and an open hole completion is performed. It may be subjected to maximum well pressures and temperatures, and must be designed to withstand such conditions.

Single Stage Cementing Operation

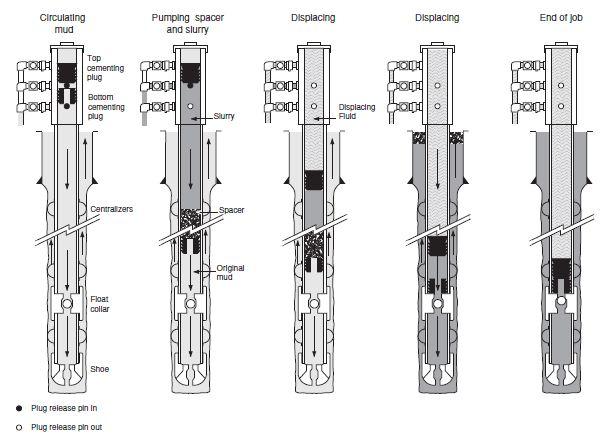

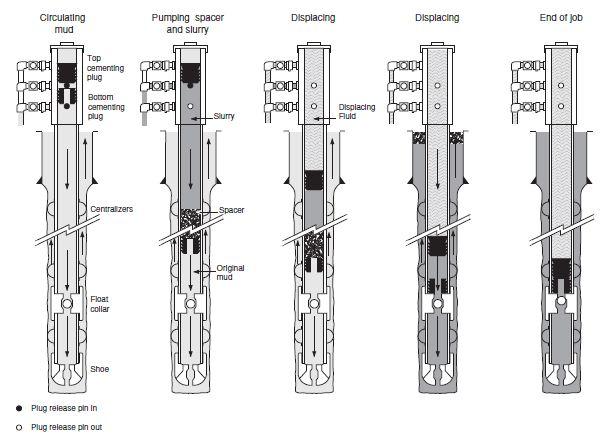

Polydrill uses this single stage cementing operation often while drilling a well, over here the casing with all of the required cementing accessories such as the float collar, centralizers etc. is run in the hole until the shoe is just a few feet off the bottom of the hole and the casing head is connected to the top of the casing. It is essential that the cement plugs are correctly placed in the cement head. The casing is then circulated clean before the cementing operation begins as shown in the picture:-

Multi-Stage Cementing Operation

Polydrill also has carried out various Multi-stage Cementing Operations to reduce :-What is a Mutli-Stage Cementing Operation?

The necessity to split the cement sheath in the annulus into two, one sheath that extends from the casing shoe to some point above the troublesome formations at the hole bottom, and the second sheath that covers shallow troublesome formations. This is normally followed for a long intermediate string of casing that is needed to be cemented. The placement of these cement sheaths is known as a multi-stage cementing operation.Contact us

POLYDRILL ENGINEERS PVT. LTD.

Phone : +91-22-26734869/ 4889

Fax : +91-22-26734901